The Future is Circular

Circularity is the future of sustainability. And what does circularity mean? We think of it as a continuous loop that renews itself, from material and manufacturing to product and recycling.

Thoughtfully made garments from recycled, natural or renewable materials, our innovative designs are moving the needle toward transeasonal circular fashion. We’re only as sustainable as the wellness of our people and communities, so our work ethos is built on inclusivity and collaboration.

Our Process

Sama Sama inherits an innate sense of responsibility to foster flourishing relationships with our suppliers, expelling this notion that you cannot develop personable understanding towards each and every person behind the making of our garments.

We work only with manufacturers who pay above minimum wage and have good working relationships with their employees, working hard to invest in good quality working conditions, equipment and contributing to advancing the skillset of their employees through further education programs.

Our Quality

At Sama Sama, we choose only high-quality natural fabrics.

Each garment is designed to be worn again and again, season after season, reducing waste and encouraging slower fashion.

As we grow, we’re building transparent relationships with our suppliers, ensuring the bigger picture is never overlooked: healthy soil, reduced pesticide use, lower greenhouse gas emissions, and respect for the people who make our clothes—with fair wages, safe conditions, and gender equality at the core.

Our Sustaining Working Relationships

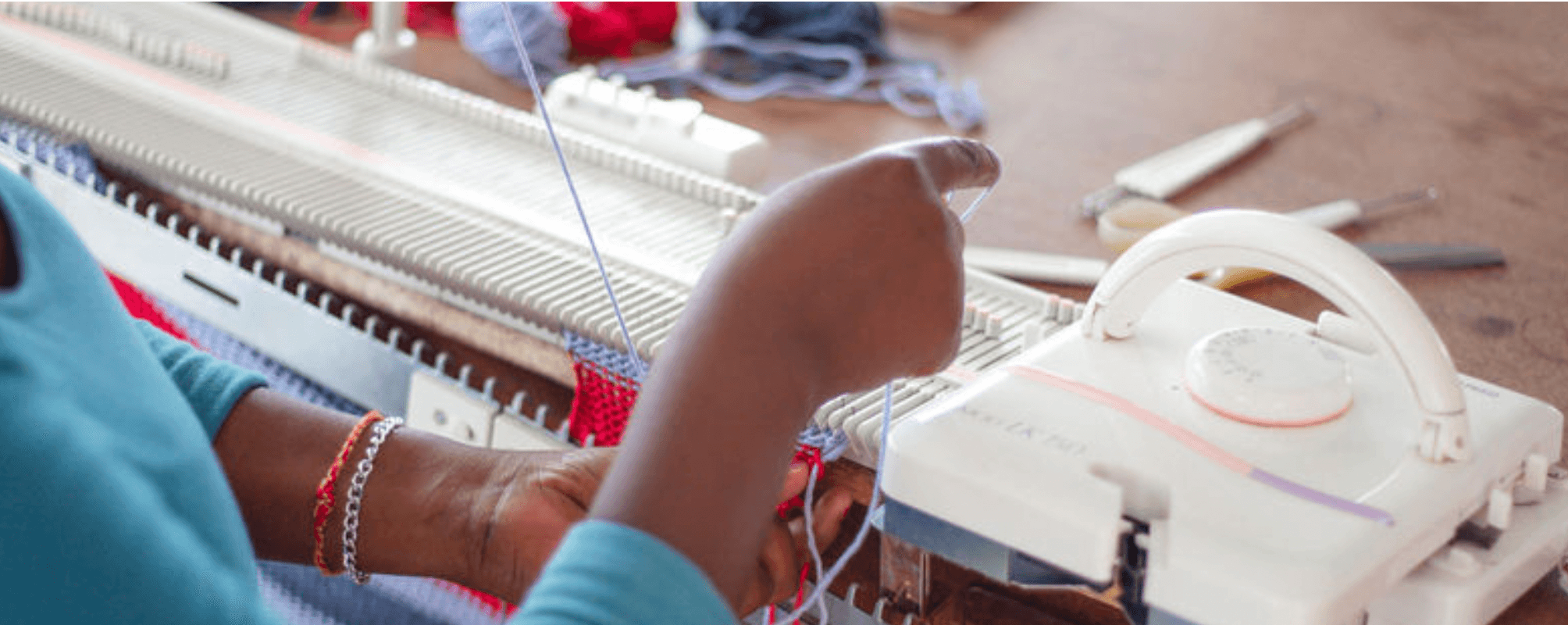

A knitting manufacturer we're very proud to work with is Nomvula’s Knitters, with knitters owning up to 51% of the business, over and above their monthly (above minimum wage) salaries.

“What started as a project in job creation, is now driving evident social and economical change.”

― Founder, Frances Becker

We work with an option of either mohair, bamboo, wool, cotton or recycled waste yarn knit fibres, which are sourced only an hour away in Port Elizabeth, giving them a strong low-carbon footprint too.

We also keep smaller pieces for any future possible garment repairs. When we have produced a style which has not sold well, or there's stock leftover after an extended period of time, we re-use these garments to create other unique designs.

Our Yarns

From farm to store, each and every process is handled with the utmost of care to ensure that the fibres are treated delicately and with the respect that they deserve.

The cotton yarn dying processes are done by hand. . From the dyeing to the balling and skeining, and the yarn is sun-dried in the factory forecourt.